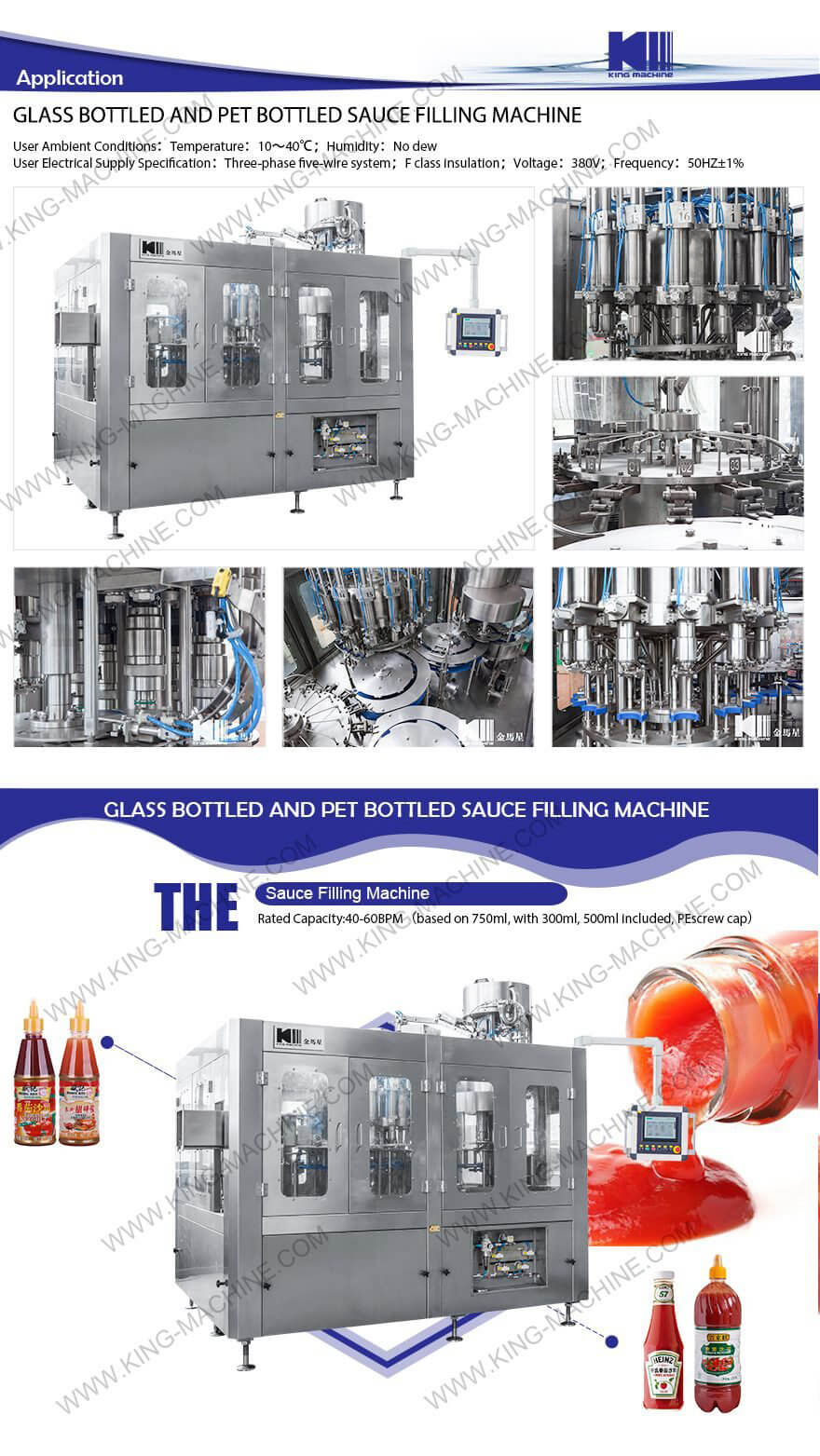

PET bottled Water Sauce Filling Machine Rated Capacity:40-60BPM(based on 750ml, with 300ml, 500ml included, PEscrew cap) Application: Sauce Jam Filling temperature: about 82℃

Product name:PET bottled Water Sauce Filling Machine

Rated Capacity:40-60BPM(based on 750ml, with 300ml, 500ml included, PEscrew cap)

Product: Sauce Jam

Filling temperature: about 82℃

Packing specification:

|

Containers and specifications |

|||||||||

|

Material |

Shape |

Filling volume(ml) |

Filling level(mm) |

Neck type |

|||||

|

PET |

Round Bottle |

750, with 500 and 300 included |

Distance to Bottle neck≤25mm |

PCO28 |

|||||

|

Adjustable specifications of the bottle type |

Customers need to buy additional change-over parts for the different bottles. If using square bottles, then bottle separating system will be added. |

||||||||

|

Packaging system |

|||||||||

|

Container Label & Control Mode |

PVC shrink labeler |

Palletizing system |

|||||||

|

Hot Melt Roll-fed |

Half-label |

Packaging system |

Min.Spec |

Palletizing requirement |

Min.Spec |

||||

|

Full Label |

Automatic |

–—– |

—– |

Manual palletizer |

—— |

||||

|

Manual |

–—– |

||||||||

Note: above data needs to be confirmed with customer.

User Ambient Conditions:

Temperature:10~40℃;

Humidity:No dew

User Electrical Supply Specification:

Three-phase five-wire system;

F class insulation;

|

Raw material |

||||||||||

|

↓ |

||||||||||

|

Volumetric filling |

← |

Blow molder |

← |

Preform |

||||||

|

Air purification unit |

↓ |

|||||||||

|

→ |

Capping |

← |

Sterile air drying |

← |

Sterile water rinsing |

← |

Cap sorter |

← |

Cap elevator |

|

|

↓ |

↑ |

↑ |

||||||||

|

Air blow dryer |

① |

Cap |

||||||||

|

↓ |

||||||||||

|

Bottle body ink jet |

||||||||||

|

↓ |

||||||||||

|

Light |

||||||||||

|

↓ |

||||||||||

|

Sleeve labeling machine |

← |

Label |

||||||||

|

↓ |

||||||||||

|

Light |

||||||||||

|

↓ |

||||||||||

|

Full bottle conveying system |

→ |

Film Shrinker |

→ |

Case conveyor |

→ |

Manual palletizer |

→ |

Finished product storage |

||

Note:Above flow chart is only for reference, which can be amended by customer’s requirement.

Main Design Parameters:

|

Item |

Design parameters |

|

|

Product sterilization |

Tubular UHT sterilization |

By the customer |

|

Cap Sterilization condition |

Ozone rinsing |

≥10s |

|

Sterile compressed air drying |

2bar,≥2s |

|

|

Filling Temperature |

Ambient temperature |

|

|

Use of filling recycle water |

Customers determine |

|

|

Use of cap rinsing recycle water |

Customers determine |

|

Note:

Above technical parameters are basic data for equipment model determination and configuration in this proposal;

Any adjustment to these data,will lead the change of equipment model and configuration